INDUSTRIAL PLANT PROJECT

WASTE ➔ ENERGY ➔ CLIMATE

Vladimir Boyko, EAASSO@yahoo.com

Lyubov Chigirinskaya, lubachigiri@yahoo.com

Edward Nisanov, Edward@nisanovtax.com

Dr. Anatoly Rokhvarger (Honorable Mention, deceased)

NOVACYCLE LLC, Brooklyn, NY

GOALS

• Save City-State NY local municipalities time and money

• Efficient processing of municipal solid waste (MSW) and commercial waste

• Elimination of landfills

• Clean energy as a byproduct of waste processing

• Prevent climate change in any possible way, while there is

still an opportunity

Current state of MUNICIPAL SOLID WASTE

INDUSTRIAL PLANT PROJECT

Landfills create problems for the environment:

• Fumes and harmful gases

• Decomposing biowaste

• Hazardous bacteria

• Global warming exacerbation

• Will take thousands of years to biodegrade

Today’s broken METHOD OF WASTE PROCESSING

• NYC and the High Acres Landfill just outside Rochester, NY

(a major disposal site for NYC) were the subjects of litigation

in 2018 due to environmental impacts of the landfill for the

nearby residents (intolerable smells, health hazards due to fumes, reductions in home market values)

• NYC agreed to settle for $60 million to cover environmental remediation

• In 2022 a local environment group filed a lawsuit against NY due to High Acres Landfill’s effects on the surrounding towns

LANDFILL GAS CONSTITUENTS

• Methane 45-60 %

• CO2 40-60 %

Traces of:

• Hydrogen Sulfide

• Benzene

• Toluene

• Ethyl Benzene

• Xylenes

LANDFILL GAS CONSTITUENTS

Accumulation of CO2 in the atmosphere traps heat, leading to global temperatures rising.

This leads to more frequent and severe weather events including heatwaves, heavy rainfall, flooding, droughts and disruption to agriculture.

About 11% of the world’s methane emission comes from landfills.

Methane is a greenhouse gas with a global warming potential about 25x greater than CO2. By enhancing the greenhouse effect, it leads to rising sea levels.

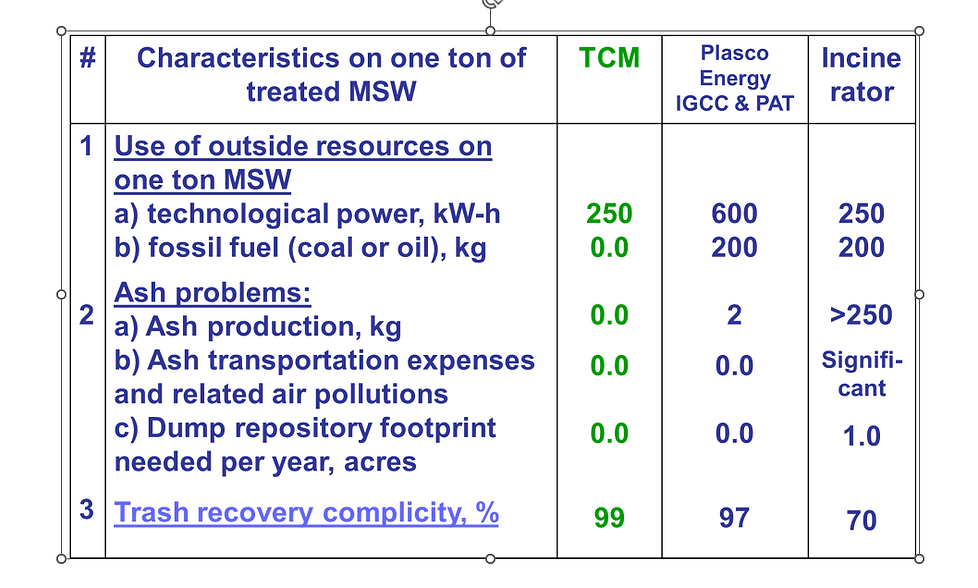

CURRENT MSW PROCESSING METHODS

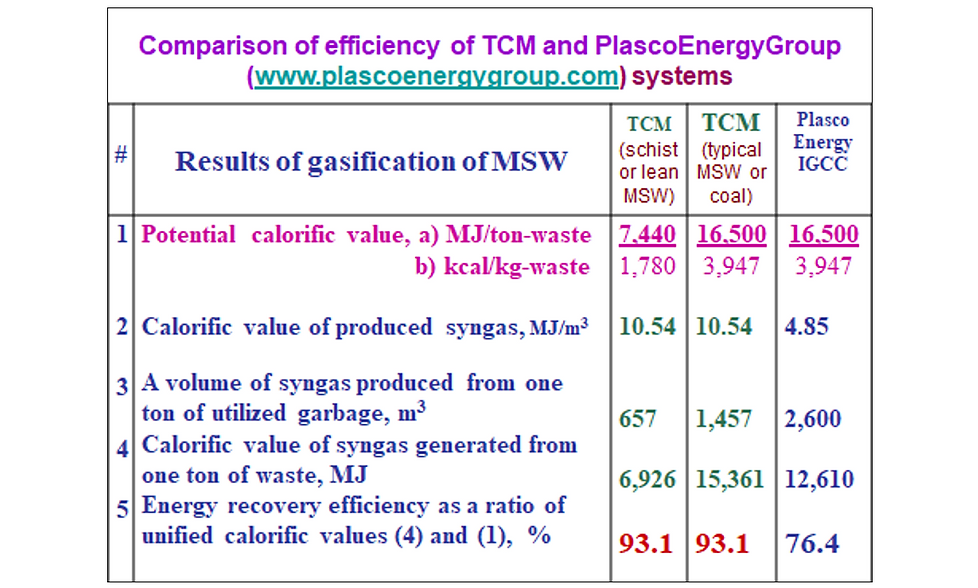

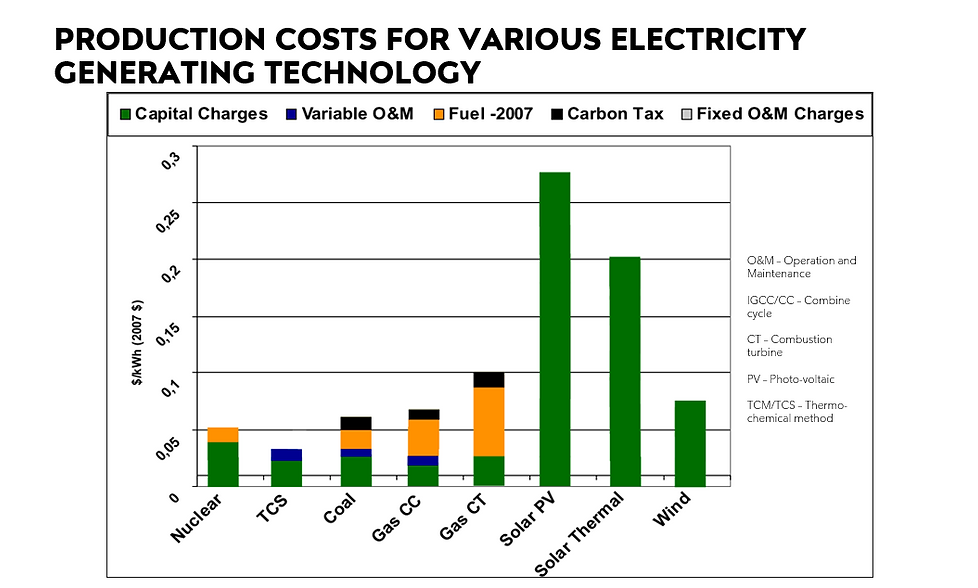

The known MSW processing method for electric power generation is Integrated Gasification Combined Cycle (IGCC) technology.

IGCC:

• Provides gasification of waste organics to hydrogen (H2) and carbon monoxide (CO) gas mixtures (syngas)

• Decreases greenhouse gas emission (compared to incinerators)

• Increases energy production

IGCC PLANT DRAWBACKS

• High capital and operational expenses

• Burdened municipal budget

• High consumption of fossil fuel, electric power and water

• Ash production and need for dump repositories

• Greenhouse gas emissions nonetheless

• Low energy efficiency

IGCC PLANT DRAWBACKS

• High capital and operational expenses

• Burdened municipal budget

• High consumption of fossil fuel, electric power and water

• Ash production and need for dump repositories

• Greenhouse gas emissions nonetheless

• Low energy efficiency

TCM METHOD

• Eliminates all drawbacks of the IGCC

• Provides significant environmental, economic, public and financial advantages for cities around the country

TCM METHOD

• Does not use outside fossil fuel nor water

• Does not produce secondary solid waste

• Does not produce hazardous gases

SYNGAS

The TCM system produces a clean and powerful fuel called syngas.

• Calorific value of 3,600kcal/kg or 10.54MJ/m3

• Hydrogen (H2) 48% and Carbon Monoxide (CO) 47% by composition

• Actual yield 0.280 ton per ton MSW with calorific value of 2,000 kcal/kg

• TCM units can work as a part of reliable electric energy transmission and distributions (T&D) systems

• Reliability-Must-Run (RMR) electricity generation stations can be placed within urban areas to maintain voltage levels in T&D systems

• TCM is the solution to the problem posed by current inefficient RMR units, which burn fossil fuels and emit greenhouse gases

SUPPORT OF T&D SYSTEMS

Annual utilization of 100,000 tons of typical urban MSW could result in:

•5,600 tons of hygienically inert multi-metal alloy

→ Can be melted down and repurposed by casting

•16,500 tons of hardened multi-component slag (no CO, CO2 nor ASH)

→ Can be used as additives in construction (pavement, concrete, bricks)

•90 tons of chemical salts and sulfur

→ Used for industrial applications and consumer goods

SOLID BY-PRODUCTS OF TCM

IGCC PLANT DRAWBACKS

• High capital and operational expenses

• Burdened municipal budget

• High consumption of fossil fuel, electric power and water

• Ash production and need for dump repositories

• Greenhouse gas emissions nonetheless

• Low energy efficiency

BENEFITS OF TCM

Provides:

• Electricity to local customers

• Clean water to community

• Metal goods

(including iron scrap)

• Building materials

• Chemical materials

• 40+ new jobs

Eliminates:

• Air pollution

• Greenhouse gases

• Ash dumps

• Use of fossil fuel

• Waste sorting requirement

• Water consumption

• Odors

Advantages compared to other methods

• Can handle all types of waste – municipal / construction / biohazards (only limitation is radioactive waste)

• Plastics

• Rubber

• Computer Boards

• Batteries

• Syringes

• Medical hazards

• Solution for sewage waste after filtration process

• Pays for itself – by products can be sold and repurposed

OUR MISSION

• Help city and town districts have cleaner air and land

• Reduce national greenhouse gas emissions to combat climate change

• Utilize full potential of MSW

•Eliminate reliance of landfills

Advantages compared to other methods

• Can handle all types of waste – municipal / construction / biohazards (only limitation is radioactive waste)

• Plastics

• Rubber

• Computer Boards

• Batteries

• Syringes

• Medical hazards

• Solution for sewage waste after filtration process

• Pays for itself – by products can be sold and repurposed

Long term Business plan

• Complete and test a lab installation of a small size operating TCM reactor

(1-2 year) in an Incubator Facility with minimal equipment. (See next slide)

• A pilot plant and a standard TCM system plant will be build (3-6 years). Each standard TCM plant with the capacity 30,000 ton/year will be paid off in 3 years.

• An industrial plant 100,000 ton/year can be achieved in 8-10 years,

or earlier if required.

• Labor for onsite construction of thermal aggregates and assembly

• Rent for land use, preferably next to landfills, for the construction

of a pilot plant

• Granting of all required permits and licenses

• Working in close cooperation with and for Citi & State NY

TIMELINE (TOTAL DURATION 2 YEARS)

1. Technical design of the TCM system ($1,000,000; 4-6 months)

2. Purchase, modification and onsite construction of thermal reactor column or a blast furness and steam heater ($3,000,000; 12 months)

3. Purchasing, delivery, assembly, and installation of engineering equipment, including scrubbers, filters, fans ($3,000,000; 12 months in parallel with #2)

4. TCM system assembly, testing and initiation ($1,000,000; 4-6 months)

5. Hiring and Training of qualified labor ($2,000,000; continuous)

● Total estimated cost $10,000,000

SHORT TERM

BUSINESS PLAN

Proposal: Development of a Laboratory-Scale Furnace to Demonstrate the Feasibility of the Patented TCM-MSW Process

• To validate the patented Thermochemical Method for processing Municipal Solid Waste (US Patent 8,197,565), we propose building a compact laboratory small-scale furnace (SSF). This small-scale system would simulate the high-temperature and high-pressure conditions of the full-scale TCM-MSW process. The purpose is to demonstrate the method’s technical viability and potential for generating zero-carbon fuel, electricity, and valuable solid byproducts.

• While the full TCM-MSW system would require approximately $70 million to implement, and a scaled-down pilot plant could be built for around $10 million by modifying a commercial blast furnace, both options present significant investment hurdles without first proving the technology's feasibility. The proposed laboratory model, costing around $1 million, offers a much more affordable and practical solution to de-risk the technology and attract further investment.

Why This Idea is a Strong Strategic Move:

1. Cost-Effective Feasibility Proof

A $1 million lab-scale furnace is a financially efficient way to validate the TCM-MSW process before pursuing much larger investments. It allows early technical demonstrations with minimal financial risk.

2. Investor Confidence & De-Risking

Demonstrating the process in a controlled lab setting builds credibility and generates critical data, making it easier to secure funding for the $10M pilot or full-scale implementation. It shifts the conversation from theoretical to practical.

3. Accelerated Innovation and Optimization

A laboratory setup enables rapid testing, data collection, and iterative improvements under real process conditions. This shortens development time and improves the system design before scaling up.

LAB OPERATING small-scale Furness DESIGNED BY COMPANY’S ENGINEERS*

PROJECT FOUNDERS

Lyubov Chigirinskaya, BS/MS in Metallurgical Engineering,

Ph.D. in Chemistry

-

25+ years of experience in Metallurgy, Corrosion of Metals Alloys, Polymer Coatings, Electrochemistry, Material Science

-

Published ~100 articles, presentations, patents

-

Professor at Tandon School of Engineering of NYU

PROJECT FOUNDERS

Vladimir Boyko, MS in Mechanic Engineering

-

Inventor and Hardware Engineer

-

45+ years of engineering, business and management experience

-

Working with waste utilization technologies development since 1984

Edward Nisanov

-

Financial Adviser

-

CEO / Owner of Nisanov Tax Group, a tax planning and consulting firm

-

20+ years of tax strategy, business development and business advisory experience

PROJECT FOUNDERS

Questions?

.jpeg)